-

Sonic Pipe

-

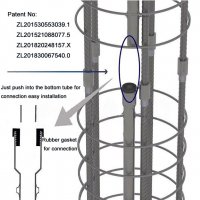

Push Fit Sonic Pipe

Push Fit Sonic Pipe

Push Fit Sonic PipeKwayt Group was founded in 2008,which is engaged in the manufacture and export of many kinds of steel pipes and fittings. Kwayt is a group company......

-

Clamp Compression Sonic Pipe

Clamp Compression Sonic Pipe

Clamp Compression Sonic PipeKwayt Group was founded in 2008,which is engaged in the manufacture and export of many kinds of steel pipes and fittings. Kwayt is a group company......

-

Spiral Sonic Pipe

Spiral Sonic Pipe

Spiral Sonic PipeKwayt Group was founded in 2008,which is engaged in the manufacture and export of many kinds of steel pipes and fittings. Kwayt is a group company......

-

Push Fit Sonic Pipe

-

Sign Post

-

Square Sign Post

Square Sign Post

Square Sign PostKwayt Group was founded in 2008,which is engaged in the manufacture and export of many kinds of steel pipes and fittings. Kwayt is a group company......

-

U Channel Sign Post

U Channel Sign Post

U Channel Sign PostKwayt Group was founded in 2008,which is engaged in the manufacture and export of many kinds of steel pipes and fittings. Kwayt is a group company......

-

Square Sign Post

- Ductile Iron Pipe

-

Steel Pipe

-

Seamless Steel Pipe

Seamless Steel Pipe

Seamless Steel PipeKwayt Group was founded in 2008,which is engaged in the manufacture and export of many kinds of steel pipes and fittings. Kwayt is a group company......

-

Welded Steel Pipe

Welded Steel Pipe

Welded Steel PipeKwayt Group was founded in 2008,which is engaged in the manufacture and export of many kinds of steel pipes and fittings. Kwayt is a group company......

-

SSAW Pipe

SSAW Pipe

SSAW PipeKwayt Group was founded in 2008,which is engaged in the manufacture and export of many kinds of steel pipes and fittings. Kwayt is a group company......

-

Seamless Steel Pipe

-

Galvanized Pipe

-

Pre-Galvanized Pipe

Pre-Galvanized Pipe

Pre-Galvanized PipeKwayt Group was founded in 2008,which is engaged in the manufacture and export of many kinds of steel pipes and fittings. Kwayt is a group company......

-

Hot Galvanized Pipe

Hot Galvanized Pipe

Hot Galvanized PipeKwayt Group was founded in 2008,which is engaged in the manufacture and export of many kinds of steel pipes and fittings. Kwayt is a group company......

-

Pre-Galvanized Pipe

- Steel Sheet Pile

-

Grouting Pipe

-

Grouting Pipe

Grouting Pipe

Grouting PipeKwayt Group was founded in 2008,which is engaged in the manufacture and export of many kinds of steel pipes and fittings. Kwayt is a group company......

-

Steel Conduit

Steel Conduit

Steel ConduitKwayt Group was founded in 2008,which is engaged in the manufacture and export of many kinds of steel pipes and fittings. Kwayt is a group company......

-

Anchor Pipe

Anchor Pipe

Anchor PipeKwayt Group was founded in 2008,which is engaged in the manufacture and export of many kinds of steel pipes and fittings. Kwayt is a group company......

-

Grouting Pipe